Home > Brinell Hardness

Brinell Hardness

Products

‘This table is as hard as a brick.’ ‘His head is like a rock.’

What do these statements have in common? Only then, you can understand what hardness testing is all about: comparing the hardness of one material to another. Unlike other attributes, hardness is a comparative measurement. Using standard testing methods, operators compare the test sample results with a known sample. Engineers and manufacturers who conduct hardness tests must select the appropriate test along with hardness scales according to their products, thickness, as well as heat-treatment procedures. Hence, hardness testing acts as a significant part of the quality control procedure.

Considering the importance of hardness testing, we provide various range of Brinell hardness testing machines as well as their accessories. Moreover, we are renowned for delivering the best well designed Brinell hardness test units that assure long-term performance.

Aoli Shenzhen Technology is an expert in manufacturing the most competitive and comprehensive range of customized hardness testers on the market solving the requirements of the buyer at an affordable cost. These hardness testers meet International standard requirements with long-term performance.

This page describes the concept of the Brinell hardness test and its application in detail. Learn how our Brinell hardness testing machines and accessories work best on larger samples with either an uneven or non-uniform grain structure.

Why Global Clients Choose Us?

25 Years of Expertise

We have 25 years of experience in the professional production of hardness testing devices, an annual output of more than 10,000 hardness testers.

Talented Engineers and support team

As of September 2020, we have a total of 125 employees, including nearly 35 professional and technical workers who are masters or doctorate degree holders.

Advanced production equipment

We have Complete machining workshop, CNC, CNC machine tools, and more than 50 other types of processing equipment,to ensure high-precision product parts.

Excellent After-Sales Service

We provided excellent after-sales service, including fast delivery, online training, immediate feedback of trouble shotting.

Need Any Help?

You tell us what you want, and we tell you our solution.

Brinell Hardness

What are the requirements of the Brinell hardness test?

Make the surface of the test object ready before executing the Brinell hardness test.

Surface preparation

Before keeping the test object in the Brinell hardness testing unit, the sample must be either:

- Ground

- Lapped

- Machined

- Polished

What is the Brinell hardness test method?

Brinell hardness is an attribute of the object and not a vital physical aspect. It is referred to as the resistance to dent by measuring the lasting indentation depth.

To make it simple, remember that while applying a static force (load) with a specified indenter, the lesser the indentation, the firmer the test sample will be. The hardness value of this indentation can be derived by assessing the deepness or the area of the dent using the Brinell test method.

The Brinell hardness testing procedure, which determines Brinell hardness, abides by the ASTM E10 standards. It is commonly used to assess materials with coarse structure or rough surfaces such as castings as well as forgings. This Brinell testing frequently utilizes a very huge test load (3000 kgf) along with an indenter having 10mm diameter. Hence, the subsequent indentation means out most of the surface as well as sub-surface discrepancies.

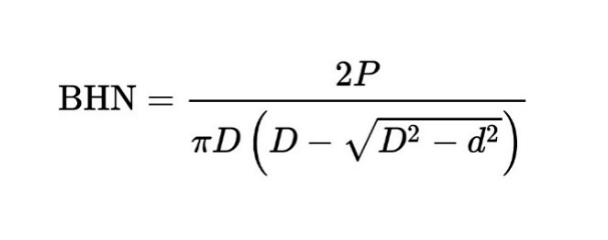

In this Brinell method, apply a fixed test load (F) on the carbide ball at a known diameter (D). Hold it for a fixed duration and remove it. The resultant impression can be then assessed with a Brinell microscope. Even an optical system can be used across two diameters at equal right angles to each other. Finally, the average values (d) of these resultant values are considered. Though the formula below can produce the Brinell number, a chart can be usually used to change the calculation of an averaged diameter finally to a Brinell hardness number.

The common test forces typically vary from 500kgf for non-ferrous materials finally to 3000kgf for steel as well as cast iron. Various other Brinell scales are available with loads as lower as 1kgf along with indenters measuring 1mm diameter, however these are rarely used.

Test Method Illustration

D = Ball diameter

d = Diameter of the impression

F = load

HB = Brinell result

For Brinell hardness testing, use reference tables to derive the value of hardness for a given indentation load and size, instead of calculating every time.

What are the details of Brinell hardness?

This Brinell test uses a steel ball with 10 mm (say 0.39 in) diameter as an indenter and 3,000 kgf force. Use only a smaller force for softer materials. When it comes to harder materials, substitute a tungsten carbide ball in the place of a steel ball. The Brinell Hardness Number can be calculated by the below formula:

where:

BHN = Brinell Hardness Number (kgf/mm2)

P = amount of load applied in kilogram-force (kgf)

D = diameter of respective indenter (mm)

d = diameter of dent (mm)

Usually, the Brinell hardness number is shown in BHN. At times, Brinell hardness is revealed in megapascals; multiply the Brinell hardness number with the acceleration due to gravity value, say 9.8 m/s2. By doing so, the final value is converted into megapascals.

Convert the BHN into the UTS, otherwise called ultimate tensile strength. Moreover, it depends upon the test material, and hence calculated empirically. This connection is created on Meyer’s index (n) derived from Meyer’s law. Moreover, if Meyer’s index becomes less than 2.2, in that case, the ratio of UTS to BHN will be 0.36. Similarly, if Meyer’s index occurs greater than 2.2, the ratio will then increase accordingly.

BHN follows the most frequently utilized test standards (ASTM E10-14 as well as ISO 6506–1:2005). In this experiment, HBW can be elaborated as follows: (H denotes hardness, B denotes Brinell as well as W denotes the material type of the given indenter, including the type tungsten (wolfram) carbide). In earlier standards, HBS or HB refers to the dimensions made with the help of steel indenters.

HBW can be determined in both their standards with the SI units given below:

where:

F = the amount of load applied (newtons)

D = diameter of indenter (mm)

d = diameter of dent (mm)

Where does the error in the Brinell hardness measurement come from?

The biggest source of the fault in Brinell hardness testing is the assessment of the relevant indentation. Because of variations in operators, while deriving the dimensions, the outcomes differ even during the perfect conditions. Lesser than perfect settings can greatly increase the variation. The test surface is frequently prepared with the help of a grinder to eliminate the surface environment. Even the pointed rough edge can make it difficult to interpret the indentation. Furthermore, when workers are aware of the specification’s parameters for rejects, these people get influenced to see the dimensions in a way that raises the proportion of ‘good’ tests with a lesser number of re-testing.

How to solve the problem of Brinell hardness measurement error?

The error issues related to the Brinell measurement can be solved in two types of technological remedies developed over all these years. The automatic optical Brinell scopes, which includes the B.O.S.S. system, utilize a computer system and an image analysis process to deliver the indentations consistently. This standardization aids in eliminating operator subjectivity. Hence, operators are less likely to see in-tolerance outcomes automatically if the sample’s outcome goes to the out-of-tolerance limit.

Brinell units, as per the ASTM E103 standards, assess the samples with the help of relevant Brinell hardness parameters along with a Rockwell hardness testing method. Hence, this process delivers the most repetitive outcomes at a greater speed. Here, the whims of optical clarifications are eliminated by using an automatic mechanical method of depth measurement.

However, these outcomes may not be strictly reliable with Brinell’s outcomes because of the various testing methods – a balance to the outcomes may be essential for several materials. It will be easier to establish accurate values in the relevant cases where this might arise as a problem.

What are the applications of Brinell hardness testing?

Brinell hardness testing can assess the copper and aluminum alloys at reduced forces along with steel as well as cast iron at an increased range of force. Since this Brinell hardness test utilizes comparatively high loads with a larger indent, it can frequently assess the hardness. Especially, it can ascertain the complete properties of the material along with local variations in hardness as well as surface conditions. All these factors make other approaches, not at all suitable, such as castings or forgings of huge parts. Highly hard steel or other relevant materials are usually not assessed by the Brinell method. Moreover, Brinell hardness testing equipment can occupy huge parts including engine castings as well as the piping with a large diameter. A minimum thickness of the material of around 8x as the testing depth is suggested as per the ISO 6506 standards. Due to the increased number of available ball loads and sizes, it can be possible to assess a varied range of hardness values with the help of the Brinell method. However, this is forced by the indenter ball itself. It can later become distorted by assessing harder materials.

Summary

As many are not experts in hardness testing, it is mandatory that the user should choose the suitable hardness assessing method as well as the respective scale, considers geometry part, test location, and testing restrictions. Failure to do so causes inappropriate interpretations regarding the hardness of the material. We help in confirming whether the specified hardness is suitable for the test material and explains how the hardness should be determined.